В целом, Цена фритюрницы для мяса может варьироваться от $1,500 к $30,000 или больше, depending on their size, design, automation level, and technical configurations. Whether you’re a small food processing business or an industrial-scale operation, knowing what drives these price differences will help you choose the right fryer that meets both your production needs and budget.

Affecting Meat Fryer Machine Price Key Factors

1.Heating Method (Electric vs. Gas vs. Thermal Oil)

Different heating sources offer different levels of energy efficiency, heating speed, and temperature control.

Electric fryers are more common in small to medium-sized setups. They’re easier to install but may have higher energy costs over time.

Gas fryers offer faster heating and are generally more cost-efficient for large-scale frying.

Thermal oil fryers are ideal for continuous production lines due to their superior heat transfer and energy conservation but come with a higher initial investment.

- Frying Capacity and Output Rate

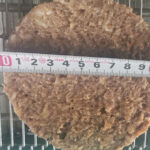

The machine’s size and how much meat it can fry per hour directly influence the cost.

A small batch fryer (20–30 kg/h) may cost $1,500–$5,000, suitable for local butcher shops or small restaurants.

Medium to large-scale continuous fryers (100–500 kg/h) can easily exceed $10,000–$30,000, depending on configuration.

- Material and Build Quality

High-grade stainless steel (usually SUS304 or SUS316) ensures durability, коррозионная стойкость, и соблюдение стандартов безопасности пищевых продуктов.

Machines with double-layer insulation, reinforced frames, and anti-rust coatings are more expensive but offer longer life cycles and safer operations.

- Automation and Control Systems

Modern meat fryer machines may come equipped with PLC touch screens, temperature sensors, oil filtration systems, and automatic feeding/discharge systems.

While manual fryers are more affordable, fully automated fryers significantly increase productivity and reduce labor costs—justifying their higher prices.

- Oil Filtration and Circulation Systems

Integrated oil filtering and circulation systems help maintain oil quality, reduce waste, and enhance product consistency.

Machines with continuous filtration systems often cost more upfront but save on long-term oil usage and maintenance.

- Cooling and De-oiling Integration

Some high-end fryers integrate cooling tunnels or de-oiling units for post-frying treatment, especially for packaged meat snacks.

These add-ons push prices up but are essential for industrial food processing lines aiming for consistent quality and extended shelf life.

Заключение: Choose the Right Fryer Based on Your Technical Needs

The meat fryer machine price isn’t arbitrary—it’s a direct reflection of its technical capabilities, production efficiency, and structural design. Whether you’re looking for a compact electric fryer or a high-capacity continuous fryer with full automation, understanding these technical factors will help you make the right investment.

💬 Found this guide helpful? Leave us a comment below and let us know what type of fryer machine you’re looking for!

🔗 Know someone who might benefit from this info? Share this blog on your social media to help your peers make smarter equipment decisions!