工业切割机彻底改变了加工效率,但使用不当的风险工人安全和产品质量. This guide details professional protocols for commercial operations.

🔧 1. Pre-Operation Setup

电压 & Grounding Check:

Verify power matches machine ratings (220V/380V) and install a leakage protector. For 3-phase systems, confirm blade rotation aligns with markings .

Blade & Component Inspection:

Remove foreign objects from cutting chambers and ensure blades rotate inward (counter-clockwise typically). Test run for 2–3 minutes max to avoid overheating .

Meat Preparation:

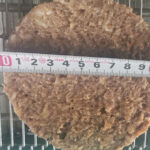

Debone thoroughly and cut into ≤40mm x 40mm strips. Frozen meat must be thawed to -6°C or above to prevent blade damage .

⚙️ 2. Step-by-Step Operation

Power On & Stability:

Lock wheel casters on mobile units and place machines on non-slip surfaces .

Feeding Protocol:

Use pusher rods (never hands!) to guide meat into the inlet. For strips/cubes:

Slices: Feed meat flat → collect output

Strips: Re-feed slices rotated 90°

Cubes: Process strips perpendicularly.

Thickness Adjustment:

Rotate the thickness dial (例如。, 2.5–40mm). Industrial models like the ASL-XRQP160 allow on-the-fly changes via control panels.

Shutdown Sequence:

Turn off power → unplug → remove residual meat before disassembly.

⚠️ 3. Critical Safety Rules

Hand Safety:

Never clear jams or adjust blades while powered. Use Kevlar gloves when handling blades.

Electrical Hazards:

Clean only with damp cloths (no water jets!). Circuit components must stay dry.

Emergency Response:

If blades jam or reverse, cut power immediately. Industrial units like Hengfan’s 3KW model include emergency stop buttons.

🛠️ 4. Maintenance for Longevity

Daily Cleaning:

Disassemble blades/combs → wash with >50°C water → dry → apply food-grade oil to prevent rust. Avoid submerging electrical parts!

Weekly Lubrication:

Grease guide rails, pusher rods, and drive shafts using NSF H1 lubricants.

Blade Sharpening:

Use manufacturer-supplied stones. Run sharpeners for 1-2 minutes post-cleaning, checking for burrs.

Long-Term Storage:

Coat all metal parts with oil, bag removable components, and store in low-humidity areas.

💎5. Key Performance Troubleshooting

| Issue | Cause | 使固定 |

|---|---|---|

| Stuck meat slices | Misaligned blades | Adjust blade gap/spacers |

| Clogged output | Over-tightened pusher plate | Loosen front nut; clear blockages |

| Motor burnout | Rusted gears from inactivity | Manually rotate blades after long storage |

✅结论

Mastering industrialmeat cutting machines ensures worker safety, reduces waste, and extends equipment life. From deboning to dicing, precision hinges on strict adherence to voltage checks, feeding protocols, and lubrication schedules.

🗨️ Have questions? Share your meat processing challenges below!

♻️ Found this useful? Tag a colleague who needs efficiency upgrades!

📩 Contact us for custom machine quotes or OEM support!