As máquinas industriais de corte de carne revolucionam a eficiência do processamento, mas o uso inadequado coloca em risco a segurança do trabalhador e a qualidade do produto. This guide details professional protocols for commercial operations.

🔧 1. Pre-Operation Setup

Tensão & Grounding Check:

Verify power matches machine ratings (220V/380V) and install a leakage protector. For 3-phase systems, confirm blade rotation aligns with markings .

Blade & Component Inspection:

Remove foreign objects from cutting chambers and ensure blades rotate inward (counter-clockwise typically). Test run for 2–3 minutes max to avoid overheating .

Meat Preparation:

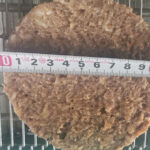

Debone thoroughly and cut into ≤40mm x 40mm strips. Frozen meat must be thawed to -6°C or above to prevent blade damage .

⚙️ 2. Step-by-Step Operation

Power On & Stability:

Lock wheel casters on mobile units and place machines on non-slip surfaces .

Feeding Protocol:

Use pusher rods (never hands!) to guide meat into the inlet. For strips/cubes:

Slices: Feed meat flat → collect output

Strips: Re-feed slices rotated 90°

Cubes: Process strips perpendicularly.

Thickness Adjustment:

Rotate the thickness dial (Por exemplo, 2.5–40mm). Industrial models like the ASL-XRQP160 allow on-the-fly changes via control panels.

Shutdown Sequence:

Turn off power → unplug → remove residual meat before disassembly.

⚠️ 3. Critical Safety Rules

Hand Safety:

Never clear jams or adjust blades while powered. Use Kevlar gloves when handling blades.

Electrical Hazards:

Clean only with damp cloths (no water jets!). Circuit components must stay dry.

Emergency Response:

If blades jam or reverse, cut power immediately. Industrial units like Hengfan’s 3KW model include emergency stop buttons.

🛠️ 4. Maintenance for Longevity

Daily Cleaning:

Disassemble blades/combs → wash with >50°C water → dry → apply food-grade oil to prevent rust. Avoid submerging electrical parts!

Weekly Lubrication:

Grease guide rails, pusher rods, and drive shafts using NSF H1 lubricants.

Blade Sharpening:

Use manufacturer-supplied stones. Run sharpeners for 1-2 minutes post-cleaning, checking for burrs.

Long-Term Storage:

Coat all metal parts with oil, bag removable components, and store in low-humidity areas.

💎5. Key Performance Troubleshooting

| Issue | Cause | Consertar |

|---|---|---|

| Stuck meat slices | Misaligned blades | Adjust blade gap/spacers |

| Clogged output | Over-tightened pusher plate | Loosen front nut; clear blockages |

| Motor burnout | Rusted gears from inactivity | Manually rotate blades after long storage |

✅ Conclusão

Mastering industrialmeat cutting machines ensures worker safety, reduces waste, and extends equipment life. From deboning to dicing, precision hinges on strict adherence to voltage checks, feeding protocols, and lubrication schedules.

🗨️ Have questions? Share your meat processing challenges below!

♻️ Found this useful? Tag a colleague who needs efficiency upgrades!

📩 Contact us for custom machine quotes or OEM support!