Operando umMáquina de serra de osso requer precisão e consciência de segurança. Este guia detalha técnicas profissionais para maximizar a eficiência e, ao mesmo tempo, prevenir acidentes ou contaminação da carne.

Etapa 1: Preparação de pré-operação

Segurança em primeiro lugar!

- Use EPI: Luvas resistentes a cortes, óculos de segurança, e avental

- Limpar espaço de trabalho: Remova detritos, sangue, ou resíduos escorregadios

- Inspeção da lâmina: Verifique se há lascas/embotamento (substitua se houver lacunas >0.5mm)

- Preparação de materiais:

- Refrigere ossos frescos para4-7° c para cortes mais limpos

- Descongele parcialmente os ossos congelados para-5° c para evitar tensão da lâmina

Etapa 2: Configuração da máquina

- Instalação da lâmina:

- Alinhe a direção dos dentes com o movimento de corte (→)

- Tensione a lâmina atépingar o som aparece (evita oscilações)

- Ajustar guia de corte:

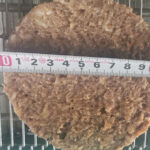

- Definir espessura (4-200mm) usando o botão de calibração

- Teste em restos de osso para precisão

- Peça segura:

- Use pinças/tornos para ossos irregulares

- Nunca segure a carne com as mãos dentro15cm de lâmina

Etapa 3: Técnicas de Corte

| Tipo de Osso | Velocidade da Lâmina | Pressão de Alimentação | Para dica |

|---|---|---|---|

| Carne/Cordeiro | Médio (800 RPM) | Empresa, impulso constante | Corte perpendicular ao grão |

| Aves | Alto (1,100 RPM) | Toque leve de pena | Apoie articulações frágeis com rede de malha |

| Congelado | Baixo (600 RPM) | Deixe a lâmina fazer o trabalho | Pulverize lubrificante de qualidade alimentar para reduzir o atrito |

Regras Críticas:

➔NUNCA forçar a passagem da carne – causa contragolpe

➔ Manter3-segundos intervalos entre cortes para evitar superaquecimento

➔ Ossos curvos? Girar peça de trabalhona direção lâmina (não contra)

Etapa 4: Protocolo Pós-Corte

- Sequência de desligamento:

- Desligue a energia → Aguarde o ponto final → Desconecte

- Limpeza (Faça dentro 10 Minutos):

- Escove os dentes da lâmina com uma escova de náilon rígida

- Lave os resíduos usando82°C água + desengordurante seguro para alimentos

- Higienize as superfícies com 70% spray de etanol

- Armazenamento de lâmina:

- Pendure verticalmente em armário seco

- Cubra os dentes com óleo mineral para evitar ferrugem

Principal 3 Erros a evitar

- Ignorando a calibração diária:

Resultado: Cortes irregulares → 15-20% desperdício de carne

Consertar: Verifique o alinhamento da guia com o calibrador de folga todas as manhãs - Ignorando sinais de vibração:

Resultado: Fratura da lâmina → estilhaços perigosos

Consertar: Aperte os parafusos de montagem se a vibração exceder a amplitude de 0,5 mm - Lâmina errada para densidade óssea:

Resultado: Carne rasgada ou motor queimado

Consertar:- 8 Lâminas TPI para ossos grossos de boi

- 14 Lâminas TPI para aves/peixes

Por que a técnica adequada é importante

CorretoMáquina de serra de osso operação:

✅ Reduz a perda de carne em até 30%

✅ Prolonga a vida útil da lâmina 6-12 meses

✅ Previne o crescimento bacteriano no pó ósseo

Chamada para ação: Achei este guia útil? Compartilhe com sua equipe de açougueiro! Tenho dúvidas sobre manutenção da lâmina ou técnicas de corte? Pergunte abaixo – nossos engenheiros respondem dentro de 24 horas! 🔧🦴

Domine seus cortes – onde a segurança encontra a precisão.