Description

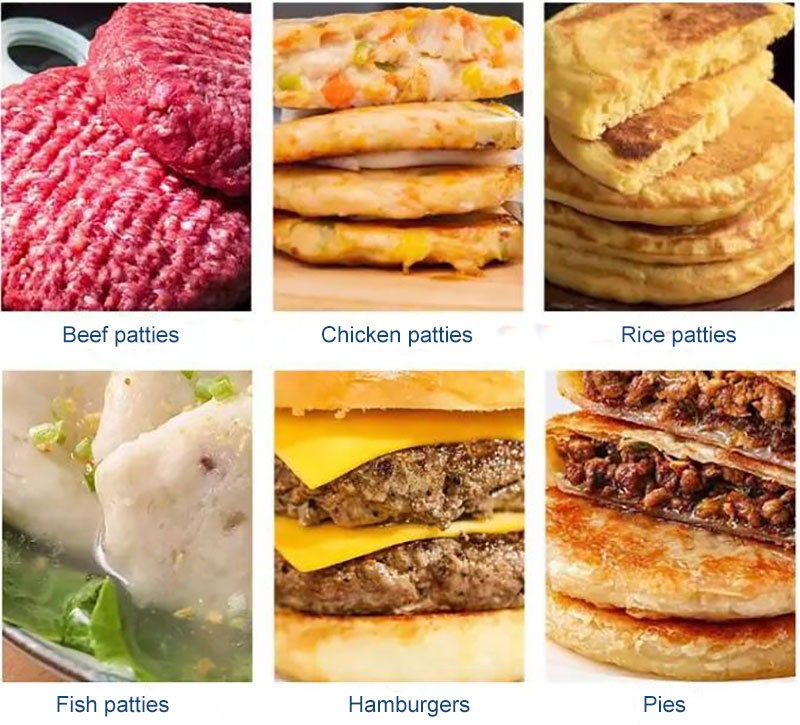

The stainless steel meat patty forming machine can automatically complete the filling, forming, pasting, output and other processes of the filling. By replacing different molds, it can produce products of different shapes. Suitable for making hamburger patties, chicken nuggets, fish cakes, potato cakes, pumpkin cakes and other foods. The whole machine is made of stainless steel, which is wear-resistant and durable and meets food hygiene standards.

Hamburger Patty Forming Machine Advantages

1. According to the different needs of customers for different products, the conveyor belt at the discharge end can be made into a belt type or a mesh belt type, and the discharge end is equipped with a water tank device to prevent product adhesion.

2. The transparent display window and magnetic induction limit switch barrel cover design are beautiful and generous, and the operation is stable and guaranteed.

3. The whole machine is made of 304 stainless steel, with firm welding and stainless steel universal brake casters, which is easy to use and move; the stirring ruler is designed as a quick-release structure, which is easy to clean and has no sanitary dead corners.

4. The automatic silk cleaning model has obtained national patent technology and is suitable for beef patties, vegetable patties, and vegetarian meat and soybean protein fiber-rich raw materials.

Application

Suitable for making hamburger patties, chicken nuggets, beef patties, fish cakes, potato cakes, pumpkin cakes and other foods. This machine is simple to operate, easy to clean, stable in performance, safe and reliable, and is suitable for use in meat processing plants, catering industries, food distribution centers and other units.

Commercial Meat Patty Machine Parameter

| Model | HFD100 |

| Power | 0.55kw |

| Voltage | 380v/50HZ |

| Barrel volume | 30L |

| Mesh Width | 130MM |

| Weight | 100KG |

| Dimension | 860*600*1400MM |

| Speed | 35-70 pieces/min |

| Capacity | About 100-300kg/h |

How To Use The Patty Forming Machine?

1. Choose a flat table and place the meat patty forming machine steadily. You can pull the chassis feet apart to make the machine panel easier to observe.

2. Insert the plug on the handheld induction head of the meat patty forming machine into the socket on the panel and tighten it. Pay attention to the positioning notch.

3. Insert one end of the power cord plug into the socket on the back panel of the chassis and the other end into the power supply socket. Please be sure to use a single-phase three-wire power supply.

4. Turn on the main power switch on the back panel of the meat patty forming machine, press the panel power switch key, and wait for the “Ready” green indicator light to light up, and the machine can work.

5. Press and hold the “Set Button” key of the meat patty forming machine and set it to an appropriate value, generally between 0.5-2.0 seconds.

6. Place the induction head on the container cover and press the start button on the handle. The red “heating” indicator light will light up, indicating that it is heating. Do not remove the induction head. After the red “heating” indicator light goes out, remove the induction head. Wait for the green “ready” indicator light to light up or the buzzer in the machine to beep briefly to prompt that the next container can be sealed.

7. Check the sealing quality of the meat patty forming machine. According to the different materials, diameters of the containers and production efficiency, appropriately adjust the “set button key to achieve the best sealing quality.

Here is the patty forming machine youtube video working process in our factory for your reference!!

Automatic Patty Forming Machine Features

The material is evenly discharged and the finished product is round

Reduce labor costs, improve work efficiency and increase satisfaction;

Diversified molds meet various market needs

Can be customized in various shapes such as heart, square, pentagon, oval, circle, triangle, etc.;

Large-capacity barrel

The large-capacity loading barrel can be filled with materials at one time, saving time, effort and labor.

Automatic sticker for meat patties

Equipped with sticker installation device, stacking does not take up space, and it is safer to contact food;

As a cornerstone of modern food automation, our automatic patty forming machine empowers meat processors and food manufacturers to achieve precision, hygiene, and scalability. With customizable molds, 304 stainless steel construction, and patented silk-cleaning technology, it seamlessly integrates into complete ready-to-cook production lines – pairing effortlessly with battering machines, breading systems, frying tunnels, IQF freezers, and automated packaging equipment. From shaping burger patties to vegan protein products, this system ensures consistent output while reducing labor costs by up to 60%.

Unlock Your Full Production Potential Today!

Whether you’re upgrading standalone equipment or building a turnkey processing line, our engineers are ready to tailor solutions to your needs.

👉 Click “Get Quote” Now to request a customized layout, technical specs, or a live demo video – let’s transform your food manufacturing efficiency together!