Popcorn chicken is a popular fast food item widely sold in restaurants, supermarkets, and frozen food chains. It is known for its crispy coating, juicy texture, and small bite-size shape. In large-scale food production, popcorn chicken is usually cooked using a commercial deep fryer or an industrial deep fryer system.

In this article, we will show how to cook popcorn chicken in deep fryer for industrial purposes. Whether you are a food factory, processing line supplier, or frozen food manufacturer, this guide will help you understand how industrial popcorn chicken deep fryer machines work and how to produce high-quality popcorn chicken at scale.

What Is Industrial Popcorn Chicken?

Industrial popcorn chicken is made from diced chicken meat (usually breast or thigh), seasoned, battered, and fried using automatic frying equipment. These small chicken bites are ideal for:

- Quick-serve restaurants (QSRs)

- Ready-to-eat frozen food

- School meal suppliers

- Airline or train catering

In an industrial setting, the popcorn chicken deep fryer is designed to handle continuous frying, with features like oil filtration, temperature control, and conveyor belt systems for automation.

Commercial Popcorn Chicken Deep Fryer Features

A commercial deep fryer for popcorn chicken is not the same as a home-use machine. It is larger, more powerful, and fully automated. Here are key features of an industrial popcorn chicken deep fryer:

- Electric or gas heating system

- Oil circulation and filtration system

- Temperature control (120°C–190°C)

- Mesh belt or twin-belt conveyor

- Auto feeding and discharging system

- Stainless steel construction (food grade 304/316)

- Oil level sensor and safety system

These popcorn chicken deep fryer machines can fry hundreds of kilograms of chicken per hour with consistent quality.

Raw Materials Preparation

To produce high-quality popcorn chicken in bulk, the ingredients and process must be standardized:

Ingredients:

- Boneless chicken meat (cut into 2.5–3 cm cubes)

- Marinade solution: salt, phosphate, water, seasoning

- Batter coating: flour, cornstarch, spices

- Predust and breading: depending on texture type

- Cooking oil: palm oil, soybean oil, or customized blend for industrial frying

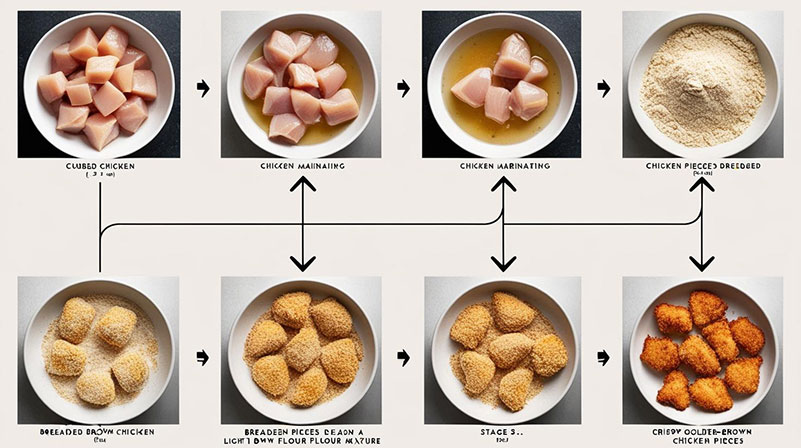

Industrial Chicken Popcorn Processing Flow

Here is a typical production line flow for popcorn chicken deep fryer systems:

- Meat Cutting Machine

Chicken breast or thigh is cut into small cube pieces. - Tumbler Marination Machine

Chicken is marinated in a vacuum tumbler with spices and moisture retention agents. - Battering Machine

Chicken is evenly coated with wet batter using an automatic battering machine. - Breading Machine (Optional)

If crispy texture is required, breading is added here. - Pre-Fryer (Optional)

A short pre-frying process helps set the coating. - Main Deep Fryer

The popcorn chicken deep fryer fries the chicken at 165°C–175°C for 2.5 to 4 minutes, depending on size and recipe. - Oil Removal & Cooling Conveyor

Excess oil is removed, and products are cooled for packaging. - Freezing Tunnel Or Quick Freezer(if frozen)

IQF (Individual Quick Freezing) system freezes the chicken to -18°C within minutes.If you are in small scale chicken popcorn business , the Quick Freezer is more suitable.Quick freezer rapidly freezes food at -18°C or lower, locking in freshness, texture, and extending shelf life efficiently with small capacity request. - Packaging Machine

Finished products are packed into bags, boxes, or bulk containers.

Popcorn Chicken Frying Tips

During production, quality checks should be done at each stage to ensure consistency. Important quality points include:

- Core temperature of chicken (must reach at least 75°C)

- Oil quality (monitor TPC levels and replace when needed)

- Color and texture (golden brown and crisp)

- Breading adhesion (no flaking or detachment)

- Shelf life (for frozen popcorn chicken: up to 12 months under -18°C)

Industrial Popcorn Chicken Deep Fryer Benefits

Using a professional deep fryer for popcorn chicken brings many advantages:

- High productivity for large-scale orders

- Uniform quality across all batches

- Energy efficiency and reduced oil usage

- Safer production environment

- Suitable for frozen, chilled, or hot-sell formats

Whether you’re selling to restaurants or exporting frozen chicken snacks, an industrial popcorn chicken deep fryer is essential equipment for modern food production.

Fried Popcorn Chicken Market Applications

Popcorn chicken produced using an industrial deep fryer is widely used in:

- Fast food chains (KFC-style menus)

- Frozen food retailers

- OEM/ODM for private labels

- Airport/stadium food services

- School lunch programs

Large orders often require stable production output and quality assurance, which is only possible through automatic frying equipment.

Final Thoughts

If you are looking to expand your popcorn chicken business or start a frozen snack production line, investing in a popcorn chicken deep fryer is a smart move. It allows for automated, consistent, and high-capacity frying, ensuring that every piece of chicken meets market standards.

By following the correct process and using professional machinery, you can produce delicious popcorn chicken that is crispy, juicy, and ready for the global market.