The meatball production manufacturing process is a vital part of modern food processing operations, offering efficient and scalable solutions for meat-based product manufacturers. As demand increases globally for ready-to-cook or ready-to-eat meatballs, food factories are turning to advanced automation and integrated meatball production line systems to improve consistency, hygiene, and output capacity.

In this blog, we will walk you through each stage of the industrial meatball production manufacturing process, highlight critical equipment in a meatball production line, and explain how automated systems can help businesses meet growing international demand.

1. Raw Material Preparation

The first step in the meatball production line is the preparation of raw meat. Typically, boneless beef, pork, chicken, or fish is trimmed and ground into a fine or coarse texture depending on the desired mouthfeel. The grinding size often ranges between 3–8 mm. Frozen meat blocks are thawed in advance using specialized defrosting equipment to preserve moisture and texture.

2. Meat Mixing and Seasoning

After grinding, the meat is transferred to an automatic mixer where it is blended with water, salt, starch, soy protein, and seasonings. This stage is critical to achieve a uniform texture and proper binding. The mixer in the meatball production line ensures even distribution of all ingredients, enhancing product consistency and taste.

Many systems use vacuum mixers to reduce air bubbles, improving density and shelf life. The final mixture has a dough-like texture suitable for shaping.

3. Forming and Portioning

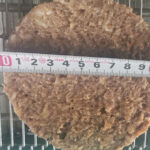

Once mixed, the meat paste is fed into a forming machine. This machine shapes the meat into uniform balls using rotary molds or hydraulic extrusion systems. Diameter and weight can be precisely controlled, often ranging between 10–30 grams per meatball.

This stage is where the meatball production line ensures high-speed, continuous output. Some advanced systems can produce up to 300–500 meatballs per minute, making them ideal for high-volume commercial production.

4. Pre-Cooking or Blanching

Depending on the recipe, formed meatballs may pass through a hot water blanching system or a steam cooker. This partial cooking step helps to set the shape, reduce microbial load, and firm the surface before freezing or further cooking. In some cases, a spiral or tunnel cooker is used as part of the integrated meatball production line to achieve consistent pre-cooking results.

5. Cooling and Drying

After blanching, meatballs are rapidly cooled using cold water or an air-cooling tunnel. Proper cooling helps stabilize the product and prepares it for freezing. Some meatball production line configurations include dewatering systems to remove excess surface moisture and prevent ice crystal formation during freezing.

6. Freezing

For frozen meatball products, an IQF (Individual Quick Freezing) tunnel is used. The meatballs are conveyed through the freezer at -18°C or lower to rapidly lock in freshness, texture, and nutrition. IQF technology prevents clumping, allowing each meatball to remain separate for easy packaging and later use.

7. Packaging and Labeling

Once frozen, the meatballs are weighed, sorted, and packed using automated machines. Vertical or horizontal form-fill-seal systems are common in the meatball production line, offering high speed and accuracy.

Packaging formats vary from retail pouches to bulk foodservice bags. Most systems also include date coding and labeling to ensure traceability and regulatory compliance.

8. Quality Control and Hygiene

Throughout the meatball production manufacturing process, quality control is essential. Key checkpoints include:

- Monitoring forming accuracy

- Checking core temperature post-blanching

- Ensuring freezing time and temperature compliance

- Oil and water quality control (if applicable)

- Visual inspection for shape, size, and surface quality

Automated meatball production lines often integrate metal detectors, checkweighers, and real-time inspection cameras to maintain food safety standards. Regular CIP (Clean-in-Place) procedures are conducted to uphold hygiene and ensure machine uptime.

Automated Meatball Production Line Benefits

An advanced meatball production line offers the following benefits:

- Consistent Quality: Automated forming and cooking ensure uniform texture and flavor.

- High Efficiency: Systems can produce thousands of meatballs per hour with minimal labor.

- Food Safety Compliance: Hygienic design and real-time monitoring reduce contamination risks.

- Scalability: Easily upgradeable lines support production growth as demand increases.

Conclusion

The meatball production manufacturing process involves a well-coordinated sequence of steps, from grinding and mixing to forming, cooking, and packaging. By investing in a modern meatball production line, food processors can enhance productivity, maintain strict quality standards, and reduce operational costs.

Whether you’re a frozen food manufacturer, a commercial kitchen, or a meat processing plant looking to scale, a reliable meatball production line is a smart long-term solution to compete in today’s global food market.

Looking to upgrade or build a new meatball production line? Contact us for a custom solution tailored to your production needs, capacity goals, and compliance requirements.