In summary, a meatball grinder is a specialized device—ranging from tabletop units to fully automated production lines—designed to grind, portion, and often shape ground meat into uniform spheres. It ensures consistency, speeds up production, and reduces labor, making it indispensable in both artisan kitchens and large-scale food processing facilities.

What Is A Meatball Grinder?

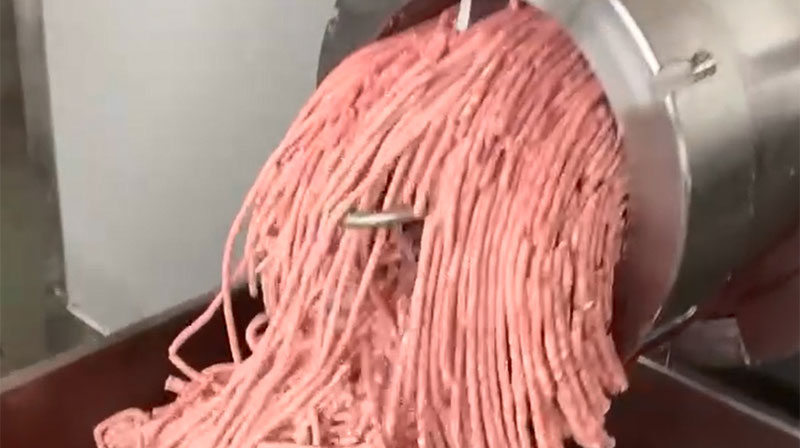

A meatball grinder combines grinding and forming functions in one machine, transforming loose meat mixtures into evenly sized meatballs without manual rolling

Types of Meatball Grinders

- Home/Tailer Models: Compact electric grinders with basic portioning plates, suited for small batches in delis or catering;

- Commercial Formers: Standalone machines that form 28–36 mm meatballs at up to thousands of units per hour, with interchangeable molds and conveyors;

- Automated Production Lines: Integrated lines linking emulsifiers, grinders, formers, and conveyors to achieve 100–120 kg/h per unit, customizable for fish, shrimp, or meat blends;

Meatball Grinder Key Features

- Stainless Steel Construction: Food-grade SUS304 ensures hygiene and easy cleaning;

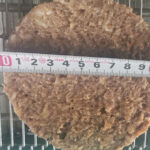

- Adjustable Ball Size: Quick-change nozzles allow precise control over diameter and weight ;

- Variable Speed Drives: Maintain consistent portioning under heavy loads;

- Integrated Conveyors: Automate transfer to ovens or packaging;

Meatball Grinder Applications

Widely used in restaurants, catering services, and industrial kitchens to produce meatballs, fish balls, and vegetable protein balls with uniform texture and weight.

Maintenance & Care

Regularly disassemble and sanitize contact parts, sharpen blades via honing steel or fine sandpaper, and follow manufacturer guidelines to prevent bacterial buildup.

By automating grinding and shaping, a meatball grinder delivers uniform quality, higher throughput, and cost savings—essential for any operation scaling meatball production.