The Meatball Forming Machine USA delivers industrial-grade performance for uniform meatball shaping and production efficiency。USA-specification machines commonly feature NSF or CE certifications to meet stringent food safety regulations.our machine provide 24/7 technical support and readily available spare parts to minimize downtime.These units integrate seamlessly into automated production lines for high-throughput operations。

Introduction

The Meatball Forming Machine USA is engineered to shape ground meat mixtures into perfectly spherical portions at rates from 200 to 1000 pcs/minute.

Built from food-grade stainless steel (304 or 316), these machines resist corrosion and simplify cleaning protocols

Powered by pure-copper or high-efficiency motors, throughput capacities often exceed 280 meatballs per minute, breaking manual output limits

Meatball Forming Machine Key Features

Hygienic Construction: All contact surfaces use FDA-compliant stainless steel for corrosion resistance and easy sanitation

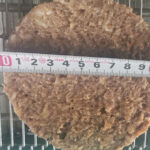

Interchangeable Molds: Five copper molds allow diameter adjustments (18–30 mm) to accommodate product variations

High-Capacity Motor: An 1100 W pure-copper motor ensures stable, continuous operation and high output rates

Easy Integration: Designed for inline connection with mixers, cookers, and freezers in a fully automated Meatball Forming Machine USA production line

Meatball Forming Machine Benefits To USA Customer

Consistent Yield: Precision servo-controlled forming heads guarantee uniform weight and shape, reducing product giveaway

Labor Savings: Automating manual shaping reduces labor costs and enhances workplace safety

Scalability: Modular design supports expansion from 210 pcs/minute to over 500 pcs/minute as demand grows

Low Maintenance: Quick-disassembly features and CIP compatibility minimize downtime for cleaning and maintenance

Buying Considerations

When selecting a Meatball Forming Machine USA, factor in:

Production Capacity: Match daily output goals (e.g., 150–300 pcs/minute vs. 500+ pcs/minute)

Power Requirements: Ensure compatibility with 220 V/60 Hz or 380 V systems depending on facility infrastructure

Certifications: Look for NSF, CE, or UL approvals to satisfy US and international regulations

Support Services: Verify availability of remote troubleshooting, spare parts kits, and installation training

Conclusion

Investing in a Meatball Forming Machine USA model elevates production consistency, reduces labor costs, and ensures compliance with US food safety standards. By choosing a certified, high-capacity machine with robust after-sales support, manufacturers can streamline operations, scale output, and compete effectively in the frozen and prepared foods market.