When exploring the Multi-function Commercial Meat Cutting Machine Price in South Africa, customers will generally find prices ranging from a few thousand to tens of thousands of US dollars. The wide range in pricing reflects differences in machine design, production capabilities, and technology integration. For businesses involved in meat processing—whether small butcheries, commercial kitchens, or large-scale food processing plants—understanding what influences the price of these machines is crucial before making a purchasing decision.

In this article, we will break down the key factors that affect the Meat Cutting Machine Price in South Africa from a technical and professional perspective. We will also explain why our machines are a top choice for African businesses and food processors seeking long-term reliability and performance.

Influencing Meat Cutting Machine Price in South Africa Key Factors

1. Machine Capacity and Throughput

The processing capacity is one of the most significant price determinants. Machines designed for small butcher shops may have capacities of 100–300 kg per hour, while high-end commercial meat cutters can handle up to 2,000 kg per hour or more. Naturally, higher throughput requires more powerful motors, better blade systems, and more robust structures—leading to a higher cost.

2. Material Quality and Construction

Machines made with food-grade 304 or 316 stainless steel are more expensive than those using cheaper materials. However, the use of high-quality steel ensures compliance with hygiene standards, simplifies cleaning, and prolongs machine durability, especially in environments with high humidity or temperature fluctuation.

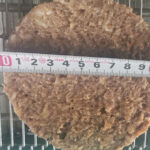

3. Blade Material and Configuration

Blade quality significantly impacts cutting precision and machine lifespan. High-end machines use stainless steel or titanium-coated blades, which offer excellent durability, hygiene, and corrosion resistance. Some models include automatic blade sharpening or multiple-blade layers, all of which can influence the final Meat Cutting Machine Price in South Africa.

4. Automation and Control Systems

Commercial meat cutting machines that are equipped with PLC touch screen controls, automatic loading/unloading systems, and programmable presets for different cutting styles are more expensive. These features not only improve efficiency but also reduce human error and labor costs—providing better ROI in the long term.

5. Cutting Functionality and Versatility

Multi-function meat cutting machines can slice, dice, shred, and strip various kinds of meat (beef, chicken, lamb, pork) using adjustable blade systems. Machines with modular design and interchangeable blades offer greater flexibility for different product types and sizes. The more cutting functions a machine offers, the more advanced its engineering—and thus the higher the price.

6. Safety Features

For commercial operations, safety is not negotiable. Machines that are designed with emergency stop systems, blade guards, overload protection, and anti-slip feet come at a premium—but these features are essential to ensure safe and uninterrupted operation.

7. After-Sales Support and Spare Parts Availability

Reliable after-sales service, availability of spare parts, and local technical support can influence the cost. Machines backed by strong manufacturer warranties and support networks typically have a higher price but offer peace of mind and reduce downtime.

Why Choose Our Multi-function Commercial Meat Cutting Machine in South Africa?

At [Your Company Name], we specialize in delivering high-performance meat cutting solutions tailored for the African market. Here’s why our machine stands out:

- Designed for African Market Needs: Our machines are built to withstand high-volume production under variable power supply and environmental conditions common in Africa.

- Versatile Functionality: Whether you are processing beef for stews, chicken strips, or minced lamb, our machine provides precise, consistent cuts with minimal waste.

- Energy Efficient & Durable: Built with industrial-grade components, our machines ensure energy savings and long-term durability—lowering operational costs over time.

- Ease of Maintenance: We provide training, manuals, and remote assistance, along with local partners in key South African cities for fast service.

- Hygienic and Safe: Our meat cutting machines comply with international food safety standards, ensuring safe, sanitary operation in commercial environments.

Our commitment is not just about delivering machines—it’s about building partnerships with food businesses across South Africa and helping them scale their operations.

Conclusion

The Meat Cutting Machine Price in South Africa is shaped by several key professional and technical factors, including capacity, blade technology, automation, and materials. Understanding these elements helps buyers make informed decisions that align with their processing needs and budget.

If you’re looking for a reliable, versatile, and high-performance commercial meat cutting machine for your business, we invite you to explore our product range. With top-tier quality and localized support, we’re here to help African food processors grow with confidence.

Was this blog helpful to you?

👉 Leave us a comment below with your thoughts or questions!

📤 Feel free to share this blog on your social media to help other professionals in the food industry discover the right meat cutting solutions.

Let’s grow the industry together—one precise cut at a time!