The industrial meat mincer machine is a core piece of equipment in commercial kitchens, food factories, and meat processing plants. Designed for high-volume grinding, this machine efficiently turns raw meat into uniform mince, ready for further processing into products like sausages, meatballs, burger patties, and more. Whether you’re a food production manager or a technician, understanding how to use industrial meat mincer machine correctly ensures product consistency, safety, and machine longevity.

In this blog, we provide a detailed, step-by-step guide on how to operate an industrial meat mincer machine, including setup, operation, cleaning, and maintenance best practices.

What Is an Industrial Meat Mincer Machine?

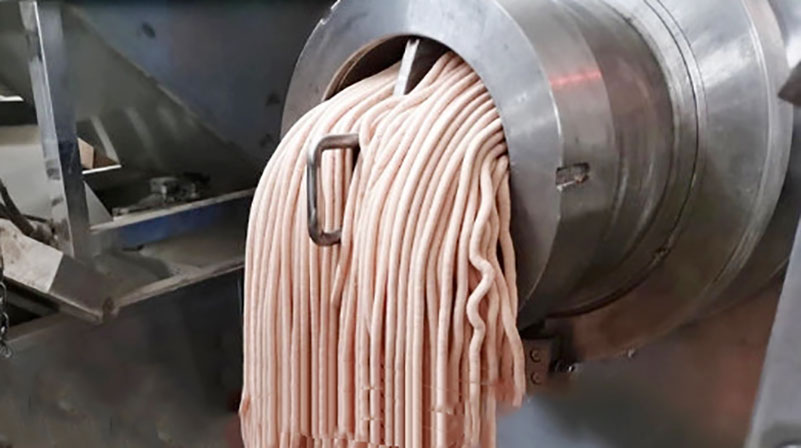

An industrial meat mincer machine is a heavy-duty grinder that processes large volumes of meat into specific grind sizes. It uses a feeding screw (worm), blades, and grinding plates to break down meat fibers, fat, and connective tissue. These machines support throughput capacities ranging from 500 kg/h to over 5000 kg/h, depending on model and motor power.

Used extensively in meat processing lines, these machines are ideal for beef, pork, poultry, and even fish. Some models can also process frozen meat blocks.

Preparation Before Use

Before you start using the industrial meat mincer machine, follow these important preparation steps:

- Inspect the machine: Check for damage, loose parts, or foreign objects inside the feed chute or hopper.

- Sanitize the components: Clean the feeding tray, auger, blades, and plates with food-grade sanitizer.

- Assemble the parts: Install the grinding plate and blade properly—blade faces the plate, and all parts must lock firmly.

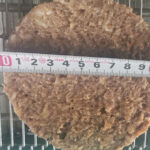

- Choose the right plate hole size: For coarse, medium, or fine grinding, select 3mm, 5mm, or 8mm plates as needed.

- Check power and safety settings: Ensure electrical connections are secure and emergency stop buttons are functional.

How To Use Industrial Meat Mincer Machine—-Step-by-Step Guide

Step 1: Load the Meat

Place pre-cut or partially thawed meat into the hopper. Avoid overfilling to maintain a steady feed rate. The industrial meat mincer machine is optimized for continuous, even feeding.

Step 2: Start the Machine

Turn on the main switch. Activate the forward rotation mode to begin grinding. Some machines also offer reverse rotation to clear blockages.

Step 3: Monitor the Grinding

Watch the output to ensure smooth and uniform mince. If output appears mushy or uneven, stop the machine and inspect the blade and plate alignment.

Step 4: Adjust as Needed

If your machine supports variable speeds, adjust the RPM depending on the type of meat and desired texture. Slower speeds are ideal for fatty meats to prevent smearing.

Step 5: Stop and Discharge

Once grinding is complete, stop the machine and wait for the auger to stop rotating. Use a scraper or pusher—not hands—to clear remaining meat.

Cleaning and Maintenance

Proper cleaning is critical to food safety and machine durability. After each use:

- Disassemble removable parts (hopper, screw, blade, plate).

- Wash in hot soapy water, then rinse with sanitizer.

- Inspect for wear and tear, especially on the blade edges.

- Lubricate key mechanical joints if required by the manufacturer.

- Perform routine maintenance, such as checking the gear oil level and motor function.

Some industrial meat mincer machines support CIP (clean-in-place) features, which streamline sanitation and reduce downtime.

Operating Industrial Meat Mincer Machines Safety Tips

- Always keep hands away from the feeding chute during operation.

- Use meat pushers to guide meat into the screw.

- Ensure all safety guards are in place.

- Disconnect power before cleaning or performing maintenance.

- Train staff on emergency stop procedures.

Industrial Meat Mincer Machines Application

The industrial meat mincer machine is used across various sectors, including:

- Meat Processing Plants – for minced beef, pork, lamb.

- Sausage Factories – preparing emulsified or coarse meat.

- Catering and Foodservice – processing large volumes of custom meat blends.

- Frozen Food Production – grinding meat for dumplings, meatballs, nuggets.

Its versatility, speed, and consistent output make it an essential asset in the meat industry.

Conclusion

Knowing how to use an industrial meat mincer machine correctly improves operational efficiency, enhances product quality, and ensures workplace safety. From setup and grinding to cleaning and maintenance, every step contributes to optimal performance and food hygiene. Investing in a high-quality industrial meat mincer machine can significantly streamline your production process and scale your business in the competitive food market.

Need help choosing the right industrial meat mincer machine for your facility? Contact us for expert guidance, machine recommendations, and customized quotes.