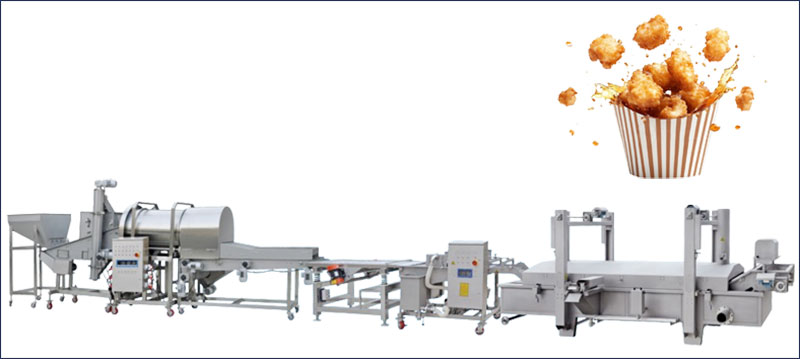

Industrial Chicken Popcorn Production Line With High‑Yield is an industrial-grade fully automatic production line designed for mass production of chicken popcorn. The equipment integrates cutting, battement, panache, continuous frying and air-cooling de-oiling, focusing on high capacity, high consistency and high quality output, and is particularly suitable for fast food factories, food processing companies and export factories.

Chicken Popcorn Production Workflow

Chicken → Cutting ↦ Conveying ↦ Battering ↦ Breading ↦ Conveying ↦ Frying ↦ Air Cooling → Finished Product

Cutting machine: Cuts chicken breast into evenly sized popcorn chicken pieces, the size can be customized to meet different specifications

Conveyor belt system: Made of 304 food-grade stainless steel, it continuously, efficiently, safely and reliably conveys raw materials or semi-finished products to the next process

Batting machine: Evenly covers egg batter or slurry through the upper and lower mesh belt spraying system, reducing waste and providing a base layer for battering

Panache (pre-breading and powder coating) machine: Use wind power and rotary agitation technology to achieve uniform powder coating of chicken pieces, improving the appearance and taste consistency of the finished product

Continuous mesh belt fryer: Fully automatic speed and temperature control, oil temperature is about 160℃, ensuring crispy outside and tender inside and golden color

Air-cooled de-oiling machine: high-speed normal-temperature air cooling and de-oiling treatment, quickly reducing surface grease and improving dry taste, suitable for subsequent packaging

Chicken Popcorn Production Line Features

Fully automatic integrated production line: covers key processes such as cutting, conveying, batter coating, flour coating, friture, and air cooling, realizing unmanned continuous operation

Food grade 304 stainless steel material: All contact surfaces are made of easy-to-clean and corrosion-resistant materials, meeting the requirements of food safety certification such as HACCP/CE

High production capacity selection: supports different levels of production from 100-600kg/h, and can flexibly configure models according to scale

Precise control system: equipped with a PLC control box, which can adjust the oil temperature, mesh belt speed, and flour coating thickness to ensure the uniform quality of each batch of products

Chicken Popcorn Processing Line Advantages

Highly consistent product quality: Constant temperature frying and uniform coating process ensure that each popcorn chicken has a consistent appearance and taste.

Significantly reduce labor costs: Automated operation reduces manual intervention, improves efficiency and reduces the chance of human error.

Flexible adaptation to a variety of raw materials: Not only suitable for chicken, but also for fish popcorn, vegetarian bean products, etc., to expand the product line.

Hygienic and easy to maintain: Modular design facilitates disassembly and cleaning, reducing cross contamination and downtime.

Fried Chicken Popcorn Machinery Benefits

Improve output and profit margin: Efficient production lines support continuous operation, significantly improving output and gross profit margin.

Open export and chain channels: Standardized quality helps popcorn chicken products enter the retail, catering or international markets.

Meet diverse market needs: Produce popcorn chicken with customized flavors, sizes, and coating styles to flexibly respond to market trends.

Enhance food safety and brand reputation: All stainless steel, automated cleaning system, and compliance certification help build high-standard factory standards.

Preuve

Several equipment suppliers we have worked with report that the modular configuration, PLC automatic control and efficient frying system of the production line support continuous high-yield output and improve quality consistency.

After a user deployed a 400kg/h production line, the output was stable, the oil consumption was controllable, and the quality was consistent. Customers reported good flavor, crispy taste, and a packaging rate of up to 98%.

The equipment has passed ISO9001/CE and other certifications, and the materials and electrical components meet international quality and safety standards, supporting global export projects.

Conclusion

Industrial Chicken Popcorn Production Line With High-Yield is a set of industrial automation equipment designed for the production of high-quality chicken popcorn, covering the entire process of cutting, battement, panache, frying and air-cooling de-oiling. The product focuses on output quality, consistency and high capacity, and has the advantages of safety, hygiene and labor saving, which is suitable for fast food processing plants, large food companies and export customers.

Welcome to leave a message online for more equipment specifications (such as capacity model, degree of automation, power/oil source solution), quotation plan and technical information. Our professional team will contact you within 24 hours to tailor a high-yield chicken popcorn production plan for you!