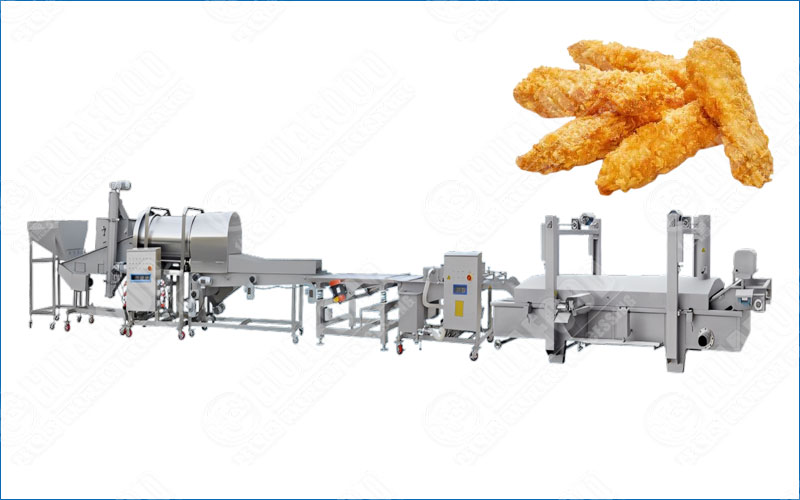

Le Complete Chicken Fillet Production Line is a turnkey system engineered to convert raw chicken breast into uniform, ready-to-use chicken fillets for ready meals, deli products, and meal kits. Designed for high efficiency, cohérence, and food safety, this production line integrates all key processing stages—marination, slicing, tenderizing, battering/coating, cooking or freezing—into a seamless flow. It ensures that every fillet meets strict quality standards for texture, yield, appearance, and hygiene.

Chicken Fillet Production Process

Raw Chicken Breasts → Marination / Tumbling → Fillet Cutting / Slicing → Tenderizing / Pressing → Battering / Coating → Cooking / Freezing → Conveyance / Conditionnement

Marination / Tumbling: A vacuum tumbling machine applies seasonings to the chicken, enhancing flavor and tenderness.

Fillet Cutting / Slicing: A chicken slicer accurately cuts breast meat into fillets/fillets of standard thickness.

Tenderizing / Pressing: A tenderizer or pounding mechanism loosens the fibers and softens the texture.

Battement / Coating: Automated battering and breading machines coat the chicken fillets with batter and breading.

Cooking / Gel: Depending on product requirements, the chicken fillets are heated or quickly frozen in a fryer, steamer, or chilling tunnel.

Conveyance / Conditionnement: The finished chicken fillets are transported via conveyor belts to packaging or boxing.

Boneless Chicken Fillet Processing Line Advantage

Enhanced Production Efficiency: Automated processes reduce manual labor, increasing throughput and consistency.

High-Quality Product Output: Maintains uniform texture and appearance, meeting industry standards for ready meals.

Évolutivité: Modular design allows for easy expansion to accommodate growing production needs.

Compliance with Food Safety Standards: Designed to meet HACCP, FDA, and CE regulations, ensuring product safety and quality.

Chicken Fillet Production Line Features

Integrated Processing Stages: Combines marination, slicing, tenderizing, battement, cooking/freezing, and packaging into a seamless workflow.

Automatic Feeding System: Utilizes a vacuum tumbler for uniform marination, enhancing flavor and tenderness.

Precision Cutting Equipment: Employs advanced fillet cutting and slicing machines to achieve consistent fillet sizes.

Flexible Cooking Options: Offers various cooking methods, including frying, steaming, or quick freezing, to suit customized requirements.

Fried Chicken Fillet Production Line Benefits

Cost Efficiency: Reduces labor costs and minimizes waste, improving overall profitability.

Quick Market Response: Accelerates production cycles, enabling faster time-to-market for new products.

Consistent Product Quality: Delivers uniform fillets that enhance brand reputation and customer satisfaction.

Easy Maintenance and Cleaning: Features tool-less disassembly and hygienic design for straightforward upkeep.

Why To Choose Us

Expertise

We have extensive experience in poultry processing equipment and are familiar with chicken fiber structure, moisture content, and heat treatment characteristics.

We possess system engineering design capabilities for multiple processes, including chicken slicing, tenderizing, revêtement, heating/freezing, Et plus.

We have a dedicated team to optimize processes, ensuring coordinated and efficient operation of the entire production line.

We also possess extensive expertise in food machinery manufacturing processes and cleaning and disinfection design (CIP/assembly and disassembly systems).

Authority

Our equipment is designed to comply with food safety standards such as HACCP, GMP, and SQF.

We can obtain NSF, UL, and 3-A food equipment certifications to meet international market access requirements.

Our company holds ISO 9001 or similar certifications, guaranteeing the quality of our equipment and manufacturing processes.

All parts that come into contact with chicken are made of food-grade stainless steel, meeting international hygiene standards.

Conclusion

En résumé, this Complete Chicken Fillet Production Line for Ready Meals Factory processes raw chicken breast into high-quality, consistent-looking, and delicious chicken fillets or tenders that meet food safety standards. The entire process encompasses key steps such as seasoning and battering, slicing, tenderizing, revêtement, heating/freezing, conveying, and packaging. It features robust technology, interconnected equipment, and integrated control.

For more information on model configurations, capacity options, power requirements, equipment cleaning solutions, or a quote, please contact us online. We will provide detailed information, case studies, and professional advice to help you build an efficient, stable, and compliant chicken fillet production line.