Opérant unmachine à scie à os nécessite une sensibilisation à la précision et à la sécurité. Ce guide décompose les techniques professionnelles pour maximiser l'efficacité tout en empêchant les accidents ou la contamination de la viande.

Étape 1: Préparation de pré-opération

Sécurité d'abord!

- Porter l'EPI: Gants résistants aux coupes, lunettes de sécurité, et tablier

- Espace de travail clair: Retirer les débris, sang, ou résidus glissants

- Inspection de la lame: Vérifiez les jetons / terne (remplacer si les lacunes >0.5MM)

- Préparation de matériaux:

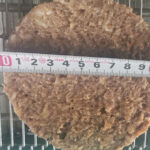

- Refroidir les os frais à4-7° C pour des coupes plus propres

- Décongeler partiellement les os gelés pour-5° C Pour éviter la tension de la lame

Étape 2: Configuration de la machine

- Installation de lame:

- Aligner la direction des dents avec le mouvement de coupe (→)

- Lame de tension jusqu'àping-ping le son apparaît (empêche les oscillations)

- Ajuster le guide de coupe:

- Régler l'épaisseur (4-200MM) Utilisation du bouton d'étalonnage

- Tester sur l'os de ferraille pour la précision

- Pièce sécurisée:

- Utilisez des pinces / poignées vides pour les os irréguliers

- Ne tenez jamais de viande à la main15cm de lame

Étape 3: Techniques de coupe

| Type d'os | Vitesse de la lame | Pression alimentaire | Pour la pointe |

|---|---|---|---|

| Bœuf / agneau | Moyen (800 RPM) | Ferme, poussée constante | Couper perpendiculairement au grain |

| Volaille | Haut (1,100 RPM) | Touche de plume légère | Soutenir les articulations fragiles avec un filet en maille |

| Congelé | Faible (600 RPM) | Laissez la lame faire le travail | Vaporiser le lubrifiant de qualité alimentaire pour réduire les frictions |

Règles critiques:

➔JAMAIS Forcer la viande à travers - provoque un pots-de-vin

➔ Maintenir3-deuxième intervalles entre les coupes pour empêcher la surchauffe

➔ os incurvés? Pièce de rotationvers lame (pas contre)

Étape 4: Protocole post-coupe

- Fermez la séquence:

- Désactiver la puissance → attendre le plein arrêt → Débrancher

- Nettoyage (Faire à l'intérieur 10 Min):

- Brosser les dents de la lame avec un pinceau en nylon rigide

- Résidu rincer en utilisant82° C + Dégreser de l'aliment

- Désinfecter les surfaces avec 70% à l'éthanol

- Rangement de lame:

- Accrocher verticalement dans l'armoire sèche

- Envelopper les dents d'huile minérale pour éviter la rouille

Haut 3 Erreurs pour éviter

- Sauter de l'étalonnage quotidien:

Résultat: Coupes inégales → 15-20% déchets de viande

Réparer: Vérifiez l'alignement du guide avec la jauge de feener chaque matin - Ignorer les signes de vibration:

Résultat: Fracture de la lame → éclats dangereux

Réparer: Serrer les boulons de montage si la vibration dépasse l'amplitude de 0,5 mm - Mauvaise lame pour la densité osseuse:

Résultat: Viande déchirée ou épuisement à moteur

Réparer:- 8 Lames TPI pour les os de bœuf épais

- 14 Pares TPI pour volaille / poisson

Pourquoi la bonne technique est importante

Correctmachine à scie à os opération:

✅ réduit la perte de viande jusqu'à 30%

✅ étend la vie de la lame par 6-12 mois

✅ Empêche la croissance bactérienne de la poussière osseuse

Appel à l'action: J'ai trouvé ce guide utile? Partagez-le avec votre équipe de boucher! J'ai des questions sur les techniques de maintenance ou de coupe des lames? Demandez ci-dessous - nos ingénieurs répondent à l'intérieur 24 heures! 🔧🦴

Maîtriser vos coupes - où la sécurité rencontre la précision.