The fish ball production line is designed to transform raw fish meat into uniform, elastic, low‑fat fish balls, optimising yield, texture, and hygiene. Let this automatic high‑efficiency fish ball production line elevate your seafood processing business with precision, speed, and consistent quality throughout.It is perfect for mackerel, cod, or tilapia formulations.

Fish Ball Manufacturing Production Process

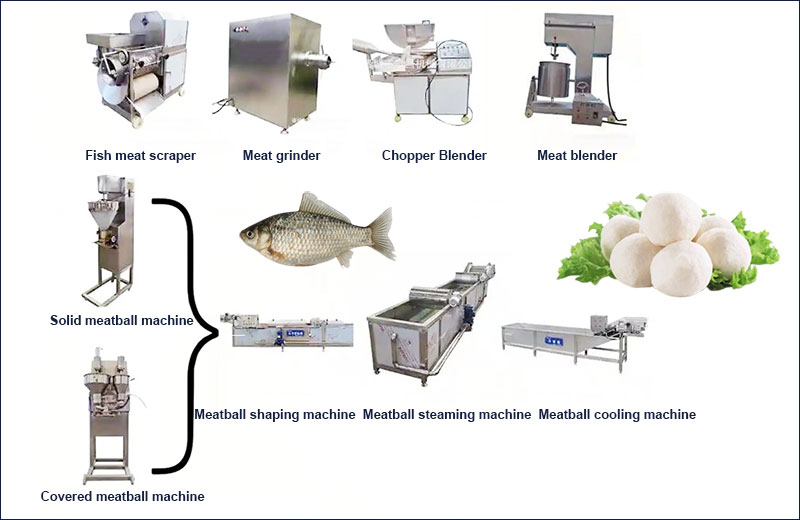

Fish descaling → Fishbone separation → Fish meat grinder and blender → Vacuum/bowl cutter (with salt and starch) → Fish ball forming machine → Steaming/blanching pot → Refrigerated cooling tank → Quality control conveyor → Packaging and weighing station

Each step is carefully designed for minimal fish‑texture damage and maximum protein gel integrity

Fish Descaling Machine (Water Sprayer/Descaling Machine): Designed specifically for descaling fish, the fish body passes through a rotating water-spraying drum, quickly removing scales without damaging the fish meat.

Fish Bone Separator/Deboner Machine: Utilizes a rotating screen to automatically separate fish bones, skin, and meat, ensuring efficient fish meat extraction.

Meat Grinder & Blender: Blends fish meat with water, ice, sel, and starch at high speed to create a milky, gelatinous paste, enhancing gelatinization and consistency.

Vacuum or Bowl Cutter: Minces and blends the fish paste under vacuum, removing air and resulting in white, finely textured fish balls.

Fish Ball Forming Machine: Utilizes an interchangeable die head and pressure pump to quickly form fish balls of a set size, ensuring consistent shapes.

Steaming/Blanching Pot (Dual Temperature Control Pre-Blanching and Cooking Pot): Utilizes two-stage steam-heated water (pre-blanching → main cooking) to ensure the fish balls’ gelatin is fully solidified and their internal elasticity remains firm.

Refrigerated Cooling Tank (Refrigerated Cooling Tank): Utilizes low-temperature circulating water to rapidly cool the fish balls, instantly locking in moisture and reducing temperature, maintaining their elasticity.

Quality Control Conveyor: An inclined conveyor transports fish balls to the inspection station, facilitating the sorting of undercooked, deformed, or contaminated products.

Conditionnement & Weighing Station (Multi-Head Weigher + Vacuum Sealing): Utilizes a multi-head weighing system for automatic vacuum bagging or sealing, ensuring the accuracy of each bag’s net weight and food safety.

Here is the crab sticks production line youtube video working process in our factory for your reference!!

💡Fish Ball Making Machine Advantages

Superior fish texture control: salt and cold‑water cooling lock in protein gel structure for chewiness and bounce.

High precision PLC logic reduces wastage of fish paste, improving yield by >10% vs. manual shaping.

Minimal manual contact lowers risk of protein denaturation or contamination, ensuring product safety.

Quick changeover of moulds and settings accommodates different fish species (tilapia, pollock, cod) and suppliers.

⭐Fish Ball Production Line Features

Entirely constructed with food‑grade 304 acier inoxydable, meeting global hygiene standards and anti‑corrosion requirements for delicate fish paste processing

PLC‑controlled, frequency‑adjustable chain conveyance, and tensioned steam‑flow water systems enable precise control over fish ball temperature and speed.

Forming capacity up to 500 pcs/min with mould sizes ranging from Ø18 to 35 mm (or larger), allowing fish ball weight control from ~8 g to 30 g or more

Integrated CIP (Clean‑in‑Place) features for all contact parts—ideal for fish oil and protein cleanup in under 30 minutes.

Two‑stage Steam‑blanching & cooking design (75 °C → 90 °C) ensures fish protein gelation without over‑boundary heat damage, preserving elastic bite

Open cold‑water cooling tank maintains ~20–25 °C for controlled shrink‑free cooling, preserving fish ball elasticity and moisture.

🎯 Fish Ball Production Line Benefits

Cut fish ball unit cost: automating reduces labor and improves yield, lowering per‑piece cost.

Consistent product quality: each fish ball has the same roundness, shine, and chewiness customers expect.

Enhanced food safety: stainless surfaces + CIP + controlled cooking temperature support HACCP/CE compliance.

Scalable output: modules can be added to increase capacity from 500 kg/h to 2‑3 tons/hour as production grows.

🧾 Evidence (proof points & case examples)

Widely deployed across 40+ seafood processing plants in Southeast Asia producing swordfish, milkfish, cod, and surimi‑based fish balls

Certified by ISO 9001, CE, and UL in multiple line configurations (500 kg/h–1500 kg/h), customizable to client country voltage (220 V / 380 V)

End‑user test reports show yield improvements of up to 15% compared to hand‑rolled fish balls.

📢 Ready to Scale Your Fish Ball Production?

If you’re targeting elastic, low‑fat, premium‑texture fish balls—this Automatic Fish Ball Production Line With High Efficiency delivers high yield, high hygiene, and high consistency.

🌐 Leave us an online message today to get:

A bespoke line layout (fish species / capacity / voltage tailored)

Detailed spec sheet & video demo of real fish ball runs

A FREE ROI comparison vs. manual or semi‑automatic methods 📩