Crispy pork skin, a popular snack and culinary ingredient, requires precise processing to achieve its signature texture and flavor. In industrial settings, this process relies on specialized equipment and optimized workflows. Below, we break down the factory production process of crispy pork skin, focusing on the continuous frying line—a key system that ensures efficiency, consistency, and scalability.

1.Pre-Treatment of Raw Materials

Before frying, pork skin undergoes essential preparation:

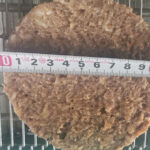

Cleaning & Trimming: Raw pork skin is washed to remove impurities and excess fat. Automated cutting machines ensure uniform thickness (typically 2–5 mm) for even frying.

Blanching: Some factories pre-treat skins with hot water or steam to soften collagen and reduce frying time. This step also helps remove residual blood and odors.

Seasoning: Brine or spice mixtures may be applied via spray systems or tumbling machines for flavor infusion.

2.Continuous Frying Process

The core of crispy pork skin production lies in the continuous frying line, which integrates advanced technologies for high-volume output.

Key Equipment Configurations

Double-Layer Conveyor System:

Utilizes upper and lower stainless steel mesh belts to sandwich pork skin, preventing floating and ensuring full oil immersion. Adjustable spacing (20–66 mm) accommodates varying thicknesses.

Example: The YP-3000 model features spiral non-stick mesh belts for smooth material transfer.

Temperature & Time Control:

Electromagnetic or gas-powered heating systems maintain oil temperature (160–190°C) with ±1°C precision.

Variable-frequency drives adjust conveyor speed, controlling frying duration (40 seconds to 5 minutes) for optimal crispiness.

Oil Circulation & Filtration:

High-temperature pumps circulate oil from the outlet to the inlet, ensuring consistent temperature and preventing hotspots.

Automatic filtration systems remove debris, reducing oil oxidation and extending usability by 10×347.

Energy Efficiency:

Oil-water mixed frying technology separates animal fat from vegetable oil, reducing waste and maintaining oil purity. This method cuts oil consumption by 50% compared to traditional fryers.

3.Post-Frying Steps

De-Oiling:Vibrating mesh belts or centrifugal systems remove excess oil, achieving a low oil content (<15%) for a lighter texture.

Cooling & Seasoning:Air-cooling tunnels rapidly lower the product temperature to prevent sogginess. Secondary seasoning (e.g., salt, chili powder) is applied via spray nozzles.

Packaging:Nitrogen-flushed packaging machines extend shelf life while preserving crispiness. Metal detectors and X-ray systems ensure food safety compliance.

4.Technical Advantages of Modern Production Line

Automation: PLC-controlled systems enable unmanned operation, reducing labor costs by 30–50%.

Hygiene: Food-grade 304 stainless steel construction and CIP (clean-in-place) systems meet international sanitation standards.

Flexibility: Modular designs allow quick adjustments for producing other snacks (e.g., fish tofu, potato chips) by replacing conveyors or paddles.

5.Quality Control & Sustainability

Real-Time Monitoring: Sensors track oil acidity (≤0.062g/100g) and peroxide values (≤1.40) to ensure compliance with food safety regulations.

Eco-Friendly Features: Low-emission fryers reduce fume concentration to 1.96 mg/m³ (1/3 of traditional fryers), aligning with green manufacturing trends.

Conclusion

Producing crispy pork skin at scale demands precision-engineered equipment like continuous frying lines. By integrating automated controls, energy-efficient heating, and rigorous quality checks, factories can deliver consistently crispy, flavorful products while minimizing operational costs. For businesses seeking to optimize production, investing in modular, multi-functional systems offers long-term scalability and adaptability.