Industrial chicken nuggets making machine lines automate every step of large-scale nugget production, from meat grinding to final packaging. These systems deliver consistent shape, texture, and throughput (300–1000 kg/h) for overseas industrial buyers.Key benefits include high efficiency, reduced labor, and uniform quality across batches.

Chicken Popcorn Production Line Configuration

An industrial line typically comprises a grinder, mixer, forming unit, battering and breading systems, continuous fryer, spiral oven, IQF freezer, and packaging.The chicken nuggets making machine at the forming stage uses interchangeable molds to produce various shapes and sizes automatically.Breading drums apply predust, batter, and crumb layers, while integrated recycling minimizes waste.

Chicken Nuggets Production Process

Ingredients and Mixing

Boneless chicken meat is ground to 1–4 mm, then mixed with water, salt, phosphate, and seasonings to create a uniform meat slurry.This blend flows directly into the chicken nuggets making machine, ensuring stable viscosity and adhesion for optimal coating

Forming, Breading, and Frying

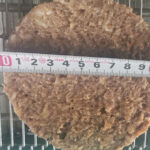

The chicken nuggets making machine forms bites that enter a multi-stage breading system. First, predust adheres via an air-flow unit, then wet batter and crumbs are applied in a continuous drum

Chicken Nugget Production Line

A flash fry at 160–170 °C sets the crust, preventing crumb loss in subsequent handling.

Full cooking follows in a spiral oven until the core reaches ≥ 75 °C.

Freezing and Packaging

Post-fry, nuggets are conveyed through an IQF tunnel at –18 °C to lock in freshness and extend shelf life up to 12 months

Automated weighers and sealers prepare final retail or bulk packaging

Chicken Nugget Production Line

Quality Control

Critical QC checks include core-temperature monitoring, oil quality (TPC levels), and visual inspections of color and coating adhesion

Regular CIP cycles ensure hygiene and uptime.

The industrial chicken nuggets making machine is the heart of a fully automated production line that delivers consistent, high-quality nuggets at scale. From meat preparation to forming, breading, frying, freezing, and packaging, every step is optimized for efficiency, food safety, and product uniformity. This solution is ideal for food factories, frozen food manufacturers, and commercial kitchens looking to expand production and meet international quality standards.

By investing in a reliable chicken nuggets making machine, you can reduce labor costs, increase output, and maintain consistent taste and texture across every batch. It’s a smart, long-term solution for businesses aiming to grow in the global food market.

If you found this article helpful, please leave a comment below to let us know your thoughts. Also, feel free to share this blog on your social media so your colleagues and friends can also learn more about this advanced food production technology. Let’s connect and grow together in the food processing industry!