The chicken nuggets making production involves a sophisticated blend of automation and precision engineering to meet high-volume demands while ensuring consistent quality. At the heart of this process lies the continuous chicken nuggets frying machine, a critical component that defines efficiency and product uniformity in modern food processing plants. This blog explores the machinery chain behind chicken nugget production, with a focus on advanced frying systems and their role in industrial-scale operations.

Chicken Nugget Manufacturing Process

Raw Material Preparation: Deboned chicken meat is ground and mixed with seasonings, binders, and preservatives.

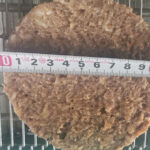

Forming: The mixture is shaped into nuggets using molders or extruders.

Breading: Nuggets pass through batter applicators and breading machines for coating.

Frying: The continuous chicken nuggets frying machine partially cooks the nuggets and sets the coating.

Freezing: IQF (Individual Quick Freezing) tunnels preserve texture and extend shelf life.

Packaging: Automated systems weigh, sort, and seal nuggets for retail or foodservice

Here is the chicken nuggets making machine youtube video working feedback for your reference!!

Chicken Nuggets Production Key Equipment

1. Continuous Chicken Nuggets Frying Machine

- Function: Cooks nuggets uniformly at 170–190°C while maintaining a steady production flow.

- Design: Features a conveyor belt system that moves nuggets through hot oil zones with adjustable dwell times (45–90 seconds).

- Innovations:

- Oil Filtration: Automated systems remove food particles, extending oil usability by 30%.

- Temperature Control: PLC systems stabilize heat distribution (±2°C accuracy) to prevent undercooking or burning.

- Energy Efficiency: Heat recovery mechanisms reduce energy consumption by 25% compared to batch fryers.

2. High-Speed Breading Systems

- Equipment: Rotary drum coaters apply batter and breadcrumbs at rates of 1,000–2,000 nuggets per minute.

- Key Feature: Vacuum coating technology ensures even adhesion, minimizing waste.

3. IQF Freezing Tunnels

- Performance: Flash-freezes nuggets at -30°C to lock in moisture and crispiness.

- Capacity: Handles up to 3 tons/hour with minimal ice crystal formation.

Why Invest in a Continuous Chicken Nuggets Frying Machine?

The continuous chicken nuggets frying machine offers unparalleled advantages:

- High throughput: Processes up to 2,000 kg/hour, meeting large-scale demand.

- Consistency: Automated controls ensure uniform cooking and oil distribution.

- Compliance: Integrates with HACCP protocols for temperature monitoring and traceability .

- Cost savings: Reduced labor and energy consumption compared to batch fryers.

The continuous chicken nugget frying machine represents a critical advancement in modern food processing, offering manufacturers the ability to scale production while ensuring consistency, safety, and cost-effectiveness. Through the integration of intelligent automation, energy-efficient systems, and stringent sanitary standards, these fryers set a new benchmark for industrial nugget manufacturing.