The fully automatic crispy fried pork skin production line integrates raw material handling, thermal processing, oil management and seasoning into a seamless workflow, producing high-quality, uniformly puffed pork skin with minimal human intervention. With stainless steel construction, precision temperature control, continuous oil filtration and programmable seasoning, the line maximizes production while ensuring consistent texture, color and taste, reducing oil consumption by up to 30%.

Pork Rinds Production Process

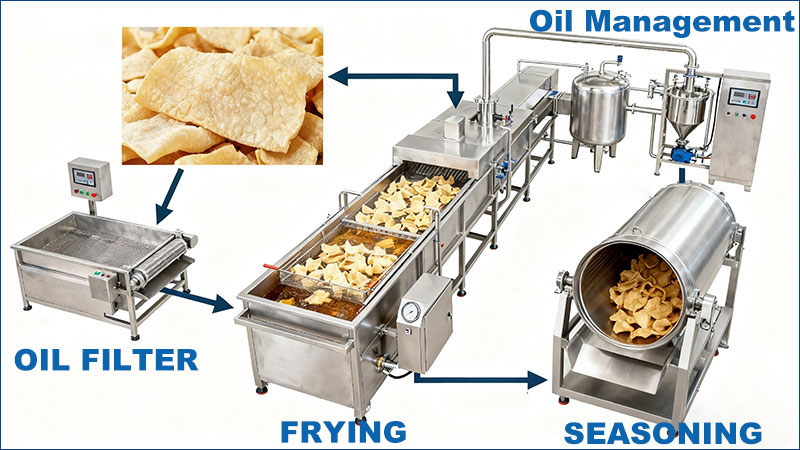

Raw Material Preparation → Blanching → Drying → Continuous Frying → Oil Filtration & Deoiling → Seasoning → Cooling → Packaging

Cutting & Washing Machine: Standardizes pork-skin strips and removes surface contaminants for uniform processing;

Blanching/Boiling Unit: Gelatinizes collagen and partially dehydrates skins in a 100–120 °C water bath to prepare for expansion;

Low-Temp Drying Tunnel: Reduces moisture to 10–15% at 60–80 °C, preventing oil splatter and ensuring crispness;

Continuous Mesh-Belt Fryer: Conveys skins through 160–180 °C oil, expanding them 4–6× and achieving golden-brown color;

Oil Filter & Deoiling Machine: Removes >99% of particulates and excess oil, extending frying-oil lifespan by 30%;

Enclosed Seasoning Drum: Applies dry or liquid seasonings evenly under gentle tumbling, programmable by batch;

Chilled-Air Cooling Conveyor: Lowers product temperature to ambient while preserving crunch ahead of packing;

Automated Weigh-Fill-Seal Packer: Delivers pre-set portions into nitrogen-flushed bags for extended shelf life;

Porks Rinds Making Machine Parameter

| Equipment | Model | Dimensions (L×W×H) mm | Power (kW) | Voltage (V) | Capacity (kg/h) |

| Cutting & Washing Machine | CW-500 | 1200×800×1100 | 2.2 | 380V/50Hz | 300–600 |

| Blanching/Boiling Unit | BQ-800 | 2000×1000×1300 | 36 | 380V/50Hz | 300–600 |

| Low-Temperature Drying Tunnel | DT-3000 | 3000×1200×1800 | 18 | 380V/50Hz | 300–600 |

| Continuous Mesh-Belt Fryer | CF-4000 | 4000×1500×1800 | 60 | 380V/50Hz | 300–600 |

| Oil Filter & Deoiling Machine | OD-800 | 1200×1000×1200 | 4.5 | 380V/50Hz | 300–600 |

| Enclosed Seasoning Drum | SD-1000 | 2000×900×1500 | 2.2 | 380V/50Hz | 300–600 |

| Chilled-Air Cooling Conveyor | CC-2500 | 2500×1000×1300 | 3.7 | 380V/50Hz | 300–600 |

| Automated Weigh-Fill-Seal Packer | PK-320 | 1200×900×1700 | 2.5 | 220V/50Hz | 20–60 bags/min |

Pork Rinds Production Line Features

Full-line Automation: Covers every step from raw-skin prep to sealed packing, minimizing manual intervention;

304 Stainless-Steel Construction: All food-contact parts meet HACCP and FDA standards for hygiene and corrosion resistance;

Precision Thermal Control: Blanching at 100–120 °C and frying at 160–180 °C for consistent expansion and color;

Continuous Oil Filtration & Deoiling: Automatic removal of solids and excess oil extends fryer life and cuts costs;

Programmable Seasoning System: Enclosed drum mixer with variable speed and dosing for exact flavor profiles;

Scalable Capacity: Modular design allows 300–600 kg/h outputs, expandable for OEM or co-packing needs;

Pork Rind Processing Line Advantages

Modular Layout: Flexible configuration adapts to available floor space and future capacity upgrades;

Reduced Labor Costs: From automatic feeding to bagging, labor requirements drop by over 50%;

Energy Efficiency: Precise oil-bath control and heat recovery options lower fuel/electricity usage by up to 20%;

Product Consistency: Digital controls ensure each batch meets exact texture, color and moisture specs;

Easy Maintenance: Quick-release belts, CIP-compatible piping and accessible panels shorten cleaning cycles;

Benefits To Customer

Premium Quality: Uniform puffing and even seasoning enhance consumer appeal.

Extended Shelf Life: Deoiled, nitrogen-flushed packaging locks in crunch for 6+ months.

Lower OPEX: Reduced oil usage, labor savings and simplified sanitation deliver rapid ROI.

Regulatory Compliance: Meets CE, UL and local food-safety standards worldwide.

This Crispy Fried Pork Rinds Production Line offers snack-food producers a fully automated, energy-efficient and scalable solution—guaranteeing consistent quality, reduced operating costs and rapid ROI. Ready to elevate your product line?

📩 Leave us a message below or contact our team to request detailed specs, floor-plan recommendations and a free, no-obligation quote today!