In the fast-paced world of food production, efficiency and consistency are paramount. For manufacturers of chicken popcorn—a popular snack enjoyed globally—the continuous chicken popcorn frying machine is a game-changer. This industrial equipment streamlines high-volume production while ensuring uniform cooking, crispiness, and compliance with food safety standards. In this blog, we’ll explore how to operate this machinery effectively, its advantages, and best practices for maintenance.

The continuous chicken popcorn frying machine is designed for large-scale operations, automating the frying process to handle hundreds of kilograms of product per hour. Key components include:

Conveyor Belt System: Transports chicken popcorn through preheating, frying, and cooling zones.

Temperature Control Unit: Maintains oil temperature (typically 165–180°C / 330–356°F) for consistent cooking.

Oil Filtration System: Removes food particles to extend oil lifespan and ensure product quality.

Automated Sensors: Monitor cooking time, oil levels, and temperature deviations.

Unlike batch fryers, this machine operates non-stop, making it ideal for meeting high demand while minimizing labor costs

How To Use Chicken Popcorn Frying Machine?

Step 1: Pre-Operation Preparation

Inspect the Machine: Check for oil leaks, conveyor alignment, and sensor functionality.

Load Oil: Fill the fryer with high-smoke-point oil (e.g., palm or sunflower oil). Avoid mixing old and new oil to prevent off-flavors.

Preheat: Set the temperature to the recommended range (165–180°C) and allow 15–20 minutes for stabilization.

Step 2: Loading the Chicken Popcorn

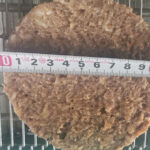

Uniform Portioning: Ensure popcorn pieces are evenly sized (typically 15–20g) to prevent uneven cooking.

Batter and Breading: Pre-dust with flour, dip in batter, and coat with breadcrumbs for optimal adhesion before loading onto the conveyor.

Step 3: Start the Frying Process

Activate the Conveyor: Adjust the belt speed to achieve a frying time of 3–5 minutes, depending on desired crispiness.

Monitor Oil Temperature: Use the control panel to ensure stability. Sudden drops may indicate overloading or mechanical issues.

Step 4: Post-Frying Handling

Cooling Zone: Transfer fried popcorn to a spiral freezer (set to -18°C) to lock in texture and prevent sogginess.

Oil Management: Activate the filtration system every 2–3 hours to remove debris and maintain oil quality

Here is the continuous chicken popcorn frying machine youtube video working feedback for your reference!!

Continuous Chicken Nuggets Frying Machine Advantages

High Throughput: Processes up to 1,500 kg/hour, ideal for large orders and export demands.

Consistency: Automated controls eliminate human error, ensuring uniform color, texture, and doneness.

Energy Efficiency: Advanced models recover heat from exhaust systems, reducing energy costs by 20–30%.

HACCP Compliance: Integrated sensors and logs support food safety protocols, critical for international exports.

Maintenance and Troubleshooting

Daily Maintenance

Clean the Conveyor: Remove residual batter and oil using food-grade degreasers.

Check Oil Quality: Test free fatty acid (FFA) levels; replace oil if FFA exceeds 2%.

Common Issues and Solutions

Uneven Browning: Adjust conveyor speed or check for temperature fluctuations.

Oil Foaming: Filter oil immediately; foaming often indicates contamination or degraded oil.

Conclusion

Mastering the continuous chicken popcorn frying machine requires a blend of technical knowledge and operational diligence. By adhering to best practices in loading, temperature control, and maintenance, manufacturers can achieve high yields, superior product quality, and compliance with global safety standards.