Chicken nuggets are a staple in fast food menus and household freezers across the globe. While they may appear simple on the surface, the chicken nuggets making process involves a series of carefully controlled industrial steps that ensure safety, consistency, and taste. In this article, we will take a closer look at how chicken nuggets are made in factory settings, from raw meat to the final frozen product.

1. Selection and Preparation of Chicken Meat

The chicken nuggets making process starts with selecting high-quality chicken meat. Factories typically use a mix of white and dark meat, often sourced from chicken breast and thighs. Once received, the chicken is inspected, deboned, and trimmed to remove any unwanted parts. It is then sent through a grinder to ensure even texture and size. This preparation phase is critical for maintaining consistent flavor and mouthfeel in the final product.

2. Blending with Seasonings and Additives

Next, the ground chicken is blended with a precise mix of seasonings, salt, spices, and food-grade additives. This mixture may also include binders like starch or flour, which help maintain the nugget’s shape and moisture during cooking. In many factories, this blending is done in large mixers that ensure uniform distribution of ingredients—an essential step in the chicken nuggets making process.

3. Forming the Nugget Shape

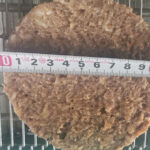

After mixing, the chicken paste is fed into molding machines that shape the nuggets. Popular shapes include rounds, ovals, or even fun forms like dinosaurs for children’s products. The molding process is automated to ensure efficiency and consistency. Every nugget is shaped to a standard weight and size, ensuring they cook evenly.

4. Coating and Breading

Once formed, the nuggets move to the breading line. This is where they are coated with a series of layers—usually a pre-dust, batter, and breading. The chicken nuggets making process here uses conveyor belts and sprayers to apply coatings evenly. Factories may use different breading styles depending on whether the nuggets are crispy, tempura, or lightly breaded.

5. Pre-Frying and Cooking

The coated nuggets are then flash-fried in hot oil for a few seconds. This step sets the breading and locks in flavor but doesn’t fully cook the meat. Some factories also use ovens to bake the nuggets at this stage. The purpose of pre-frying is to prepare the product for freezing while maintaining texture.

6. Freezing and Packaging

After pre-frying, the nuggets go through a freezing tunnel where they are rapidly frozen to preserve freshness and prevent bacterial growth. They are then weighed, packed, and sealed in bulk or retail packaging. This is the final step of the chicken nuggets making process, ensuring the nuggets are ready for transport to stores or food service providers.

7. Quality Control and Safety Measures

Throughout the chicken nuggets making process, strict quality control checks are performed. These include temperature monitoring, microbiological testing, and visual inspections. Food safety is paramount in factory environments, and many manufacturers comply with global standards like HACCP or ISO 22000.

Conclusion

Understanding the chicken nuggets making process helps consumers appreciate the technology and precision involved in mass-producing this popular food item. From sourcing raw chicken to shaping, breading, and freezing, each step is optimized for safety, taste, and efficiency. Whether you enjoy nuggets at home or from a fast-food restaurant, their journey from factory to fork is nothing short of fascinating.